News Update - September 2025

Engineering notes

The final tank steadying brackets have now been fitted to the firebox sides.

A local panel beater is making corner sections of cladding around the firebox backhead.

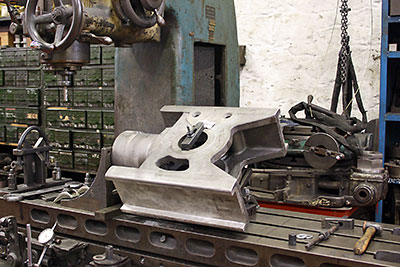

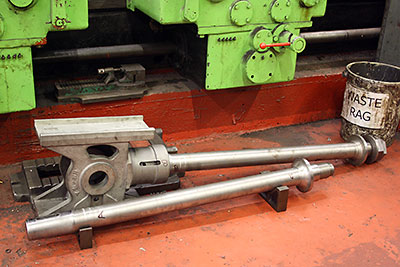

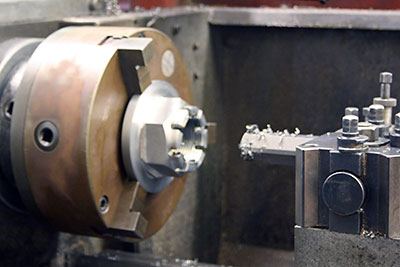

Machining of the slot for the taper cotter in each crosshead continues. Machining of the valve spindle crossheads continues as does parts for the gradient pins of the coupling rods.

The vacuum pipework is largely complete except for the final section from inside the left-hand main frame up to the ejector on the side of the smokebox. This will have to wait until the ejector is fitted. Unfortunately the BR drawings which show the vacuum and carriage warming pipework are rather lacking in dimensions, there is nothing to detail a length of straight pipe and radius of bends, etc. so it is a case of studying the drawing and photographs to relate bends and so forth to other aspects of the chassis and making a best guess.

A short section of the carriage warming pipe has been fitted on the right-hand side of the loco but the right-hand tank needs to be fitted in order to continue the pipe run to where it turns inside the main frame.