About the Trust

The project started life in the late 1990's under the aegis of South Devon Railway fireman John Besley, who worked hard to get the new locomotive off the ground until 2003 when work and family commitments forced him to hand over the controls to Cheshire-based SVR footplatemen driver Tony Massau and fireman Chris Proudfoot.

Initially, The 82045 Locomotive Fund (as it was then known) maintained a fairly low profile, though a great deal of hard work was being done behind the scenes in order to put the project on a sound footing. The Fund has built up a rapidly growing nucleus of enthusiastic and supportive members and is quietly confident of success with this comparatively simple, practical newbuild scheme.

The flood damage experienced by the SVR between summer 2007 and spring 2008 caused us to put our plans on hold to some extent, as it did not seem right to promote ourselves too vigorously at a time when our home Railway itself need all the help it could get. However, since mid-2008 the 82045 project has moved on apace. SVR volunteers laid down an excellent reinforced concrete base at our dedicated site at Bridgnorth in June 2008, and in November the locomotive's frame plates - cut, profiled and machined before the floods - were delivered to Bridgnorth after drilling at Boro' Foundry in Lye (Stourbridge) and installed in holding jigs made by Tony Massau (see News Update November 2008).

Other large components inherited from John Besley (two pairs of buffers, reportedly from an 08 diesel but of the correct type, and the chimney from Class 3 Mogul no.77014), previously held in Cheshire, are now at the SVR. The Trust has a sizeable collection of smaller parts, including driver's brake valve and brake valve pedestal, sanding gear, firehole doors, lamp brackets, bunker steps, assorted grab- and handrails and many other items. We have also built up a large library of BR drawings of the 82000 class, and these have proved invaluable at all stages of building the frame assembly, enabling the main frames to be cut, profiled and machined; the smokebox saddle, buffer beams, principal stretchers and dragbox assemblies to be fabricated; and patterns to be made for the cast horn guides, horn blocks, firebox support bracket, pony truck centres and buffer beam gusset brackets.

We have now completed the engine's chassis at Bridgnorth. The final frame stretcher - the cast firebox support bracket - was installed between the frames in mid-August 2011, as was the smokebox saddle (see News August 2011). The latter enabled the front dragbox assembly, which had been stored ready since the early part of the year, to be fitted. Please see below for an explanation of these terms if you are not sure.

At the time of writing (April 2014), the engine is on the verge of a transformation in its appearance, to a rolling chassis with cylinders and bunker in situ. The driving (more accurately "coupled") wheels, after casting and machining in the Black Country at Boro' Foundry, have been pressed on to their axles and fitted with tyres at the South Devon Railway's Buckfastleigh Works, and should be ready for return to Bridgnorth in the near future. Meanwhile, the cylinders have been cast by Cerdic Foundries and, after de-stressing, have arrived at Williton on the West Somerset Railway for final machining. At Bridgnorth, work is at present concentrated on completing the riveting at the rear of the chassis; ensuring that the axle box assemblies are ready for the coupled wheels to be fitted; and proceeding with the front and rear pony trucks. The bunker is also due to be fabricated following a generous offer by a member to sponsor it. This will be necessary as well as eye-catching, since the handbrake handle is mounted on the front of the bunker and we need to be able to stop the engine when it becomes a rolling chassis. Riveting of the frame assembly is being undertaken by the Trust's engineering team at its twice-weekly working parties, with assistance from time to time from SVR boilersmith Ross Cooper.

The arrival in late 2012 of the forgings for the two connecting rods marked the first stage in our acquisition of the various components of the Walschaert’s valve gear, and the cylinder account is being kept open for the receipt of funds for these, while the necessary finance for the complete cylinder job is safely ring-fenced.

Following the outstanding success of the Wheel Appeal, launched in March 2012, the main focus of fund-raising has now switched to the boiler and firebox, though money continues to be raised for the wheel account in respect of the pony assemblies. 82045 has the same rear pony truck assembly as the smaller Riddles Class 2MT 2-6-2 tank, and we have a friendly working relationship with the Bluebell-based Standard Class 2 Group who are building no. 84030 at Sheffield Park. The first fruit of this has been the pony truck cradle, cast by a firm in South Yorkshire, and the order to cast the pony wheels (we have hired the pattern from its owners) is due to be issued shortly. The Boiler Appeal was launched in the March 2014 issue of SVR News, and will be introduced in stages over the coming months in order to spread the fund-raising net to the wider enthusiast market. The SVR's own Bridgnorth Works is interested in tendering for the boiler job, and contracts will be awarded as soon as funds permit. The registration of the Trust for VAT in the Spring of 2013 has given a huge boost to our fund-raising and has shortened the timescale to completion by at least eighteen months.

We have no personal ambitions with 82045: we simply want it to be built and would be more than happy to build it on behalf of a benefactor, the only criterion being that the engine should be based on the SVR, though available for hire to other heritage lines.

We consider that the SVR is an ideal home: it has a 16-mile operating length, steam railway engineering know-how that is unsurpassed in modern Britain, and it is also historically correct for this locomotive since examples of the class worked over the line throughout the 1950's and early 1960's. What we did not anticipate in the early days was that we would have the great good fortune to assemble the wonderfully varied and highly skilled team of volunteer engineers who work on 82045. This has enabled many jobs that would otherwise have had to be put out to contract to be done in-house, and continues to save us many thousands of pounds. It is hoped that as much as possible of the work that our team cannot undertake will be done under contract by the SVR at Bridgnorth.

Although based on the SVR, the Trust is an independent body. An earlier tie with the "Hengist" project was terminated by mutual consent in 2003, and the only affiliation now is with the BR Standard Locomotive Owners' Group (BRSLOG), an informal consortium of individuals and organisations concerned with the surviving (and planned newbuild) Riddles locomotives. This meets twice a year and is a valuable forum for cooperation as well as providing an interesting overview of the status quo of all these locos.

How the Trust Began

John Besley, the originator of the scheme (and not to be confused with John Beesley of footplate clothing & equipment supplies!), writes about the germination of the idea behind building the next BR Standard class 3 tank engine, 82045.

Glossary of Terms

frame stretchers are fabricated steel components that fit between the frames and impart strength and rigidity to the locomotive's chassis. They are of varying shapes and sizes (see photographs in News section).

horn guides fit into the gaps in the frames and correctly locate the axleboxes of the leading and trailing driving wheels.

horn blocks do the same job for the centre pair of driving wheels on 82045, these wheels actually doing the work of propelling the loco. The horn block is a very substantial piece of kit, as befits an item that has to contain the considerable stresses involved in propulsion.

the smokebox saddle is a two-and-a-half ton fabrication which sits firmly between the frames. The cylinders are bolted on to each side, and the structure is surmounted by an arc-shaped seat ("saddle") on which the smokebox rests.

Page updated: 20 October, 2025

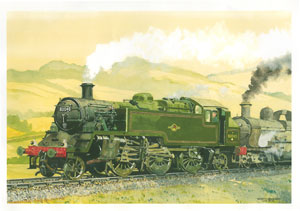

What might have been: in this scene, painted by Edinburgh based railway artist Robin Barnes, an almost-new 82045 pilots a GWR 'Dukedog' on the Cambrian in the spring of 1956.

82023 in lined black livery.

82019 waiting to depart Sidmouth station. Photo: Colour Rail

82019 at Southampton Docks, 8th June 1964.

Photo: Colour Rail

82019 - again! Nine Elms shed 14th March 1967.

Photo: John Wickham

82037, Cheddar. September 1962. Photo: A J Pike

82020 in plain green livery, Towyn. Photo: Colour Rail

82030 at Swindon Works freshly outshopped in lined green livery. 18th October 1959. Photo: K L Cook