News Update - December 2023

Engineering notes

By Tony Massau

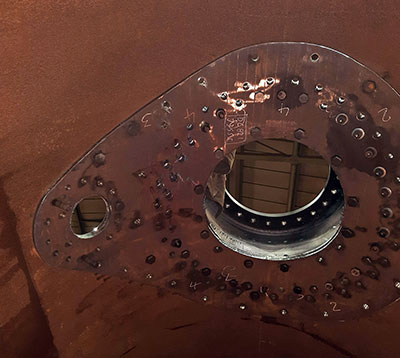

Various holes have appeared in the boiler barrel in recent weeks. The hole for the dome has been cut out and also the hole for the regulator gland and likewise for one of the boiler feed water clacks at the time of writing. The dome has been placed in position on the barrel and all the rivet holes drilled. The dome has been bolted down through the barrel and the doubling plate inside. In due course the bolts will be exchanged for rivets.

A recent activity has been making the brackets which are fixed to the sides of the boiler barrel to which are attached links to support and steady the water tanks. As can be seen in the photo of a hot bracket being squeezed in the hydraulic press the work entailed in making various brackets often involves making some sort of jig to assist in producing the required shape, all of which is time and labour consuming.

Seasons greetings to all our readers.

Chairman’s Chat – December 2023

Chairman's Chat - December 2023 - our regular insight into the 82045 wider world is now online.

The boiler barrel in Bridgnorth boilershop. Photo: Tony Massau.

Three photos of the boiler barrel with the dome in place. Photo: John Pagett

Heating up a tank steadying bracket preparatory to bending to shape. Photo: John Pagett.

Bending a tank steadying bracket to the required shape. Photo: Peter Line.